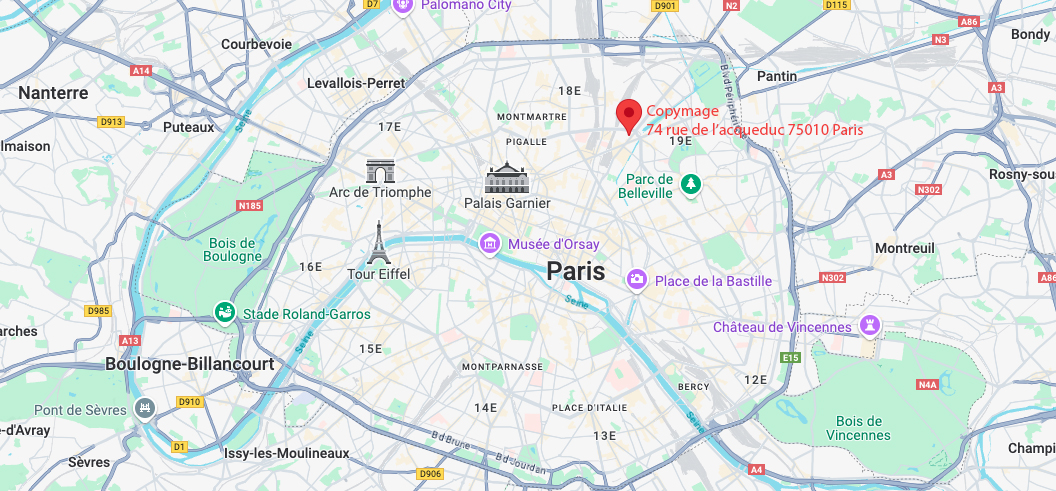

- 📦 ON DÉMÉNAGE !🏭 COPYMAGE INTÈGRE L'IMPRIMERIE NOEL : 74, Rue de l'Aqueduc 75010 Paris✨ Nous allons faire la même chose, mais à un autre endroit ! ✨

- 📦 ON DÉMÉNAGE !🏭 COPYMAGE INTÈGRE L'IMPRIMERIE NOEL : 74, Rue de l'Aqueduc 75010 Paris✨ Nous allons faire la même chose, mais à un autre endroit ! ✨

- Call us 01 42 61 00 33

Monday to Friday 9:00 - 18:00 IMMEDIATE

CUSTOMISED QUOTERETRAIT EXPRESS

& LIVRAISON J+1-

-

- All

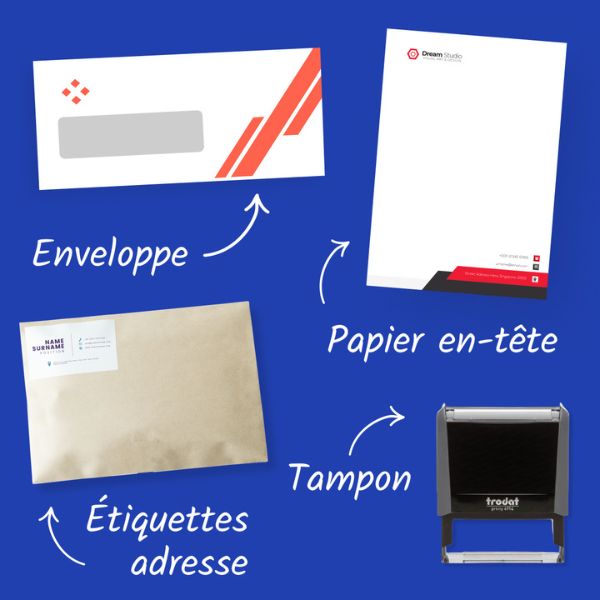

products - Cards

- Brochure

Files - Advertising

- Printing

- Office automation

- Adhesives

- Signage

- Themes

- Printing

Express in 4H

Tips & tricks from your printer

All you need to know about the different broaching techniques ?

Perhaps you've heard the term "binding" before without knowing what it refers to? This term, which originated in the publishing world but is sometimes used in the printing industry, has a common perimeter with the more familiar term "binding".

In this article, we propose you to discover what the binding technique is by presenting you a quick history of this notion. We will then list the 3 binding techniques that you can choose from by calling your professional printer. Finally, we will present you the main differences between "binding" and "binding" in the publishing world.

What is broaching?

The term "binding" refers to the process by which soft cover sheets are assembled to form a book or magazine.

In the last century, bookbinding was the most widely used binding process. It was done with the help of a stitching machine, a book sewing machine operated by printing professionals. These specialized workers from the publishing world assembled, folded and sewed the pages of the future books into flexible sections of about ten pages. The signatures were then assembled in the order in which they were to be read and attached to the cover with a strong weave or by means of a gluing technique.

With the industrial revolution, the publishing industry has seen a rise in mechanization which has replaced these finishing operations. From now on, all the binding steps can be carried out by a single digitally controlled machine. This machine allows a large number of binding operations to be carried out in a short time.

Broaching achieves several objectives:

- It holds the pages of a document together

- It facilitates the opening and consultation of the document

- It reinforces the solidity and thus the durability of the document

- It protects the document from deterioration due to handling

- It enhances and beautifies the document

Thus, binding remains a popular binding technique in the publishing industry for theprinting of books. It is, for example, frequently used in the production of paperbacks and school books.

3 types of binding for the binding of your documents

Three binding techniques are used by your professional printer for the binding of your communication materials. The choice of the best binding technique depends mainly on three factors:

- the number of pages in your document,

- the use you intend for this document,

- the look you want to give to your document.

We detail hereafter the techniques of binding by specifying the supports of communication for which they are more indicated:

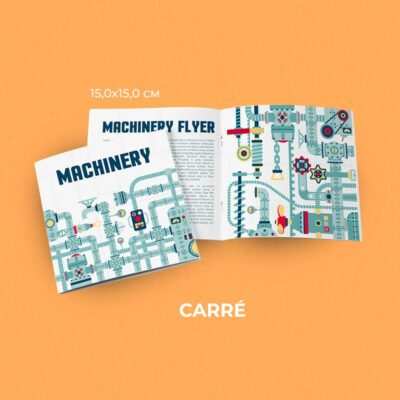

- Square-back binding: a professional look

The glued square back binding allows to bind a large number of pages to a cover (often of a higher grammage) using a PUR glue (reactive polyurethane glue) which ensures a very high adhesion of the sheets and a great resistance to the support. The glued square back binding method offers a very qualitative rendering close to the books found in bookstores. Its serious aspect is perfectly suitable for the binding of doctoral thesis but, associated with finishes such as a selective varnish or a gilding for the cover, it is also to be privileged for the realization of high-end product catalogs.

- Spiral binding: a flexible binding

Spiral binding is the easiest, fastest and most efficient way to bind documents. It allows to bind documents with a large number of pages in a functional way. A spiral folder has the advantage of opening completely flat. This binding method is therefore ideal for binding training books on which users can easily take notes - provided that uncoated paper is chosen for the inner pages.

- The stapled binding: a strong and elegant binding

Stapled binding (also called "saddle stitching" or "two-stitch metal") is the most economical method of binding. It allows for the production of magazines and booklets that are easy to consult, resistant to handling and professional in their appearance. It is ideal for publications with a smaller number of pages (between 4 and 96 depending on the paper weight). However, the number of pages must be a multiple of 4.

What is the difference between binding and stapling?

At your professional printer, the terms "binding" and "binding" are often used interchangeably, although the term "binding" is most often used. In the publishing world, the difference between "binding" and "binding" is more pronounced, and is primarily related to the type of book cover.

- Paperback books are books that have a soft cover. Books that use a paperback method are more economical to produce than bound books. The signatures that make up the book are cut, scored and glued together to the cover - which is made of a slightly heavier weight paper than the inside pages. The result is flexible books such as: pocket books, magazines or school books.

- Bound books require more work: the sections are sewn together and then assembled to a hardcover. They are more solid, more durable over time. Among the bound books, you will find comic books, cookbooks, art books, etc. Their manufacturing cost is higher but the result is more qualitative. Bound books are preferred by collectors.

We hope this article has given you a better understanding of what binding is and what techniques you can use to bind your documents with a professional printer. At Copymage, we will be happy to advise you on the best binding techniques for your projects.

Our rates

The best prices on the market

The quality

We are demanding and attentive to your satisfaction

Our deadlines

Tight deadlines thanks to our continuous production system

Imprim'vert label

We are careful about our footprint and waste management. We have obtained the Imprim'vert label.

Help & Advice

Our experts are here to help you.

HELP & ADVICE

Our experts are here to help you. Do not hesitate to contact them.

Adresse

74 rue de l’Acqueduc 75010 Paris

Métro

Ligne 2, 5, 7 : Stalingrad

Ligne 7; 7B : Louis Blanc

Bus

Lignes : 26, N42, 45, 48